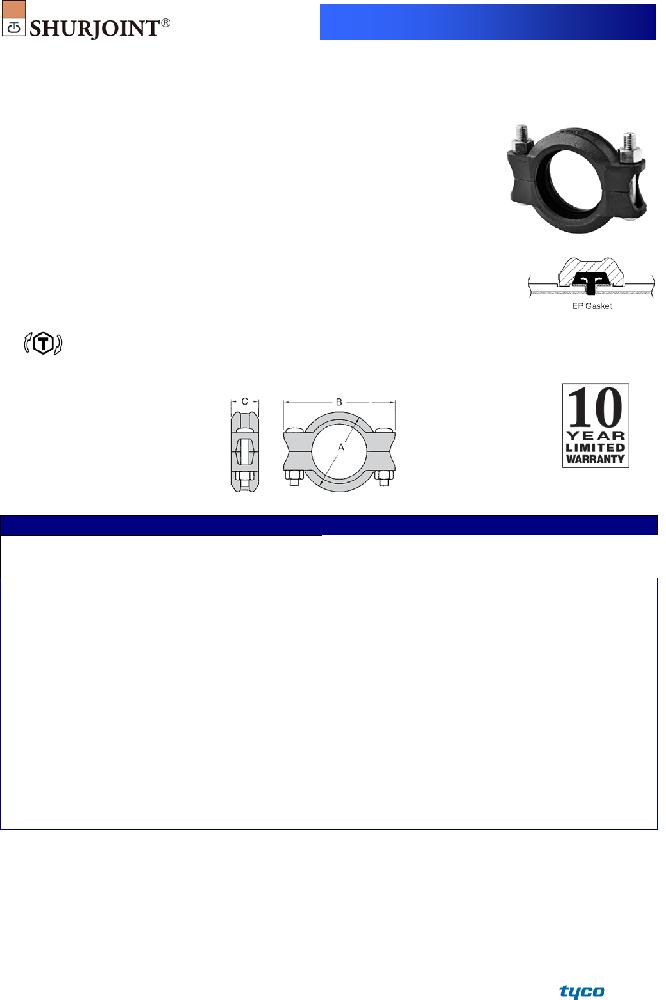

MODEL XH-70EP EXTRA HEAVY RIGID COUPLING

With End Protection (EP) Gasket

The Shurjoint Model XH-70EP coupling is an extra heavy rigid coupling for use with plastic coated pipe, cement-lined pipe or Sch. 40S or 80S stainless steel pipe. The coupling is capable of holding high pressure up to 2,500 psi (175 Bar) depending on pipe size when used in conjunction with machined EP cut-grooves and the applicable pipe. The coupling housings are painted black and supplied with an EP (End-Protection) gasket, which will permit a continuous connection of lined-surface of the pipe and also protect the pipe ends from corrosion. The standard EP gaskets are made of oil-resistant Nitrile compound.

XH-70EP couplings are not allowed to install on standard or commercial roll- or cut- grooved pipes. Pipe ends shall always be prepared with the EP Cut-Grooves which is shown in page 2.

Always use the XH-70EP coupling with an EP (End-Protection) gasket. Do not use a C-shaped standard gasket with a XH-70EP coupling.

Always fasten the bolts to the required torque.

Full warranty terms can be found on www.shurjoint.com

Model XH-70EP Extra Heavy Rigid Coupling with EP Gasket

|

|

Max. |

ASME/ANSI |

Max. |

|

|

|

|

|

|

|

|

|

|

Working |

Pressure Class |

End |

|

Dimensions |

|

|

Bolt |

|

|

|

Nominal |

Pipe |

Pressure |

Rating^ |

Load |

|

|

|

|

|

Bolt |

|

|

A |

B |

C |

No. |

Size |

Weight |

|

Size |

OD |

(CWP)* |

@100oF/@38oC |

(CWP) |

Torque |

|

in |

in |

PSI |

PSI |

Lbs |

in |

in |

in |

|

in |

Lbs - Ft |

Lbs |

|

mm |

mm |

Bar |

Nom. Class |

kN |

mm |

mm |

mm |

|

|

N-m |

Kgs |

|

2 |

2.375 |

2500 |

2500 |

11070 |

3.54 |

5.90 |

1.92 |

2 |

⅝ x 2¾ |

60 - 90 |

3.3 |

|

50 |

60.3 |

175 |

CWP |

50.0 |

90 |

150 |

49 |

80 - 120 |

1.5 |

|

|

|

|

2½ |

2.875 |

2500 |

2500 |

16220 |

4.06 |

6.61 |

1.92 |

2 |

⅝ x 2¾ |

60 - 90 |

4.0 |

|

65 |

73.0 |

175 |

CWP |

73.2 |

103 |

168 |

49 |

80 - 120 |

1.8 |

|

|

|

|

3 |

3.500 |

2500 |

2500 |

24040 |

4.80 |

7.40 |

2.00 |

2 |

⅝ x 2¾ |

60 - 90 |

4.8 |

|

80 |

88.9 |

175 |

CWP |

108.6 |

122 |

188 |

51 |

80 - 120 |

2.2 |

|

|

|

|

4 |

4.500 |

2500 |

2500 |

39740 |

6.18 |

8.74 |

2.17 |

2 |

¾ x 4¾ |

74 - 170 |

8.8 |

|

100 |

114.3 |

175 |

CWP |

179.5 |

157 |

222 |

55 |

100 - 235 |

4.0 |

|

|

|

|

6 |

6.625 |

2000 |

2000 |

68910 |

8.58 |

11.61 |

2.25 |

2 |

⅞ x 5½ |

125 - 200 |

17.6 |

|

150 |

168.3 |

140 |

CWP |

311.3 |

218 |

295 |

57 |

170 - 275 |

8.0 |

|

|

|

|

8 |

8.625 |

2000 |

2000 |

116790 |

10.83 |

14.33 |

2.75 |

2 |

1 x 5½ |

200 - 300 |

24.0 |

|

200 |

219.1 |

140 |

CWP |

527.6 |

275 |

364 |

70 |

275 - 400 |

10.9 |

|

|

|

|

10 |

10.750 |

1250 |

1250 |

113400 |

13.15 |

16.70 |

2.95 |

2 |

1 x 5½ |

200 - 300 |

31.2 |

|

250 |

273.0 |

88 |

CWP |

514.8 |

334 |

424 |

75 |

275 - 400 |

14.2 |

|

|

|

|

12 |

12.750 |

1250 |

1250 |

159510 |

15.35 |

18.90 |

2.95 |

2 |

1 x 5½ |

200 - 300 |

36.7 |

|

300 |

323.9 |

88 |

CWP |

724.7 |

390 |

480 |

75 |

275 - 400 |

16.7 |

|

|

|

|

* Working pressure is based on EP cut grooved XS, Sch. 80 pipe.

^ The ASME/ANSI pressure class rating is not the design or maximum pressure rating, rather is provided for those that are accustomed to specifying or using ASME/ANSI pressure class rated components such as flange, valves, etc.

C-09-1/3 Rev.K 20130218

MATERIAL SPECIFICATIONS

• Housing:

Ductile Iron to ASTM A536, Gr. 65-45-12 and or to ASTM A395 Gr.65-45-15, min. tensile strength 65,000 psi (448 MPa).

• Surface Finish:

Black enamel.

• Rubber Gasket:

Grade “T” Nitrile “EP” gasket (Color code: Orange stripe) Recommended for petroleum products, air with oil vapors, vegetable and mineral oils within the specified temperature range.

Also good for water services under +150oF (+66oC).

Temperature range: -20 oF to +180 oF (-29 oC to +82 oC).

Do not use for HOT WATER above +150 oF (+66 oC) or HOT DRY AIR above +140 oF (+60 oC)

• Bolts & Nuts:

Heat treated carbon manganese steel track bolts to ASTM A449-83a (or A183 Gr. 2), minimum tensile strength 110,000 psi (758 MPa), Zinc electroplated, with heavy-duty hexagonal nuts to ASTM A563

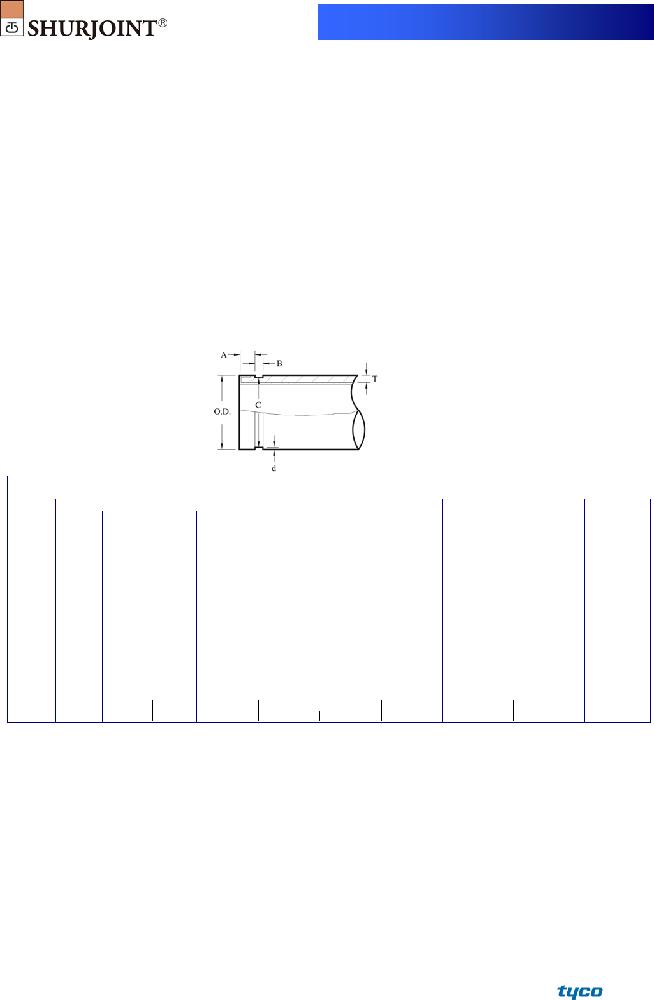

“EP” End Protection Cut Grooving Dimensions for XH-70EP Couplings

|

|

|

|

Pipe O. D. |

|

Gasket Seat A |

|

Gasket Width B |

Groove dia. C. |

|

Grv. |

|

Nom. |

|

|

|

|

|

Cut Groove |

|

Cut Groove |

|

Depth d |

|

Size |

|

|

|

Tolerance |

|

|

|

|

|

Tol.+0.25/ |

|

|

|

|

|

|

|

Basic |

+ |

- |

Basic |

|

Tol. ± |

|

Basic |

+0.010 |

Basic |

Tol. +0 / +0. |

|

(ref.) |

in |

|

in |

|

in |

in |

in |

|

in |

|

in |

in |

in |

in |

|

in |

|

mm |

|

mm |

|

mm |

mm |

mm |

|

mm |

|

mm |

mm |

mm |

mm |

|

mm |

|

2 |

|

2.375 |

|

+0.024 |

-0.024 |

0.562 |

|

±0.010 |

|

0.255 |

-0.005 |

2.250 |

-0.015 |

|

0.063 |

|

50 |

60.3 |

+0.61 |

-0.61 |

14.27 |

|

±0.25 |

6.48 |

-0.13 |

57.15 |

-0.38 |

1.60 |

|

2½ |

2.875 |

+0.029 |

-0.029 |

0.562 |

|

±0.010 |

0.255 |

-0.005 |

2.720 |

-0.018 |

0.078 |

|

65 |

73.0 |

+0.74 |

-0.74 |

14.27 |

|

±0.25 |

6.48 |

-0.13 |

69.09 |

-0.46 |

1.98 |

|

3 |

3.500 |

+0.035 |

-0.031 |

0.562 |

|

±0.010 |

0.255 |

-0.005 |

3.344 |

-0.018 |

0.078 |

|

80 |

88.9 |

+0.89 |

-0.79 |

14.27 |

|

±0.25 |

6.48 |

-0.13 |

84.94 |

-0.46 |

1.98 |

|

4 |

4.500 |

+0.045 |

-0.031 |

0.605 |

|

±0.015 |

0.305 |

-0.005 |

4.334 |

-0.020 |

0.083 |

|

100 |

114.3 |

+1.14 |

-0.79 |

15.37 |

|

±0.38 |

7.75 |

-0.13 |

110.08 |

-0.51 |

2.11 |

|

6 |

6.625 |

+0.063 |

-0.031 |

0.605 |

|

±0.015 |

0.305 |

-0.005 |

6.455 |

-0.022 |

0.085 |

|

150 |

168.3 |

+1.60 |

-0.79 |

15.37 |

|

±0.38 |

7.75 |

-0.13 |

163.96 |

-0.56 |

2.16 |

|

8 |

8.625 |

+0.063 |

-0.031 |

0.714 |

|

±0.015 |

0.400 |

-0.010 |

8.441 |

-0.025 |

0.092 |

|

200 |

219.1 |

+1.60 |

-0.79 |

18.14 |

|

±0.38 |

10.16 |

-0.25 |

214.40 |

-0.64 |

2.34 |

|

10 |

10.750 |

+0.063 |

-0.031 |

0.714 |

|

±0.015 |

0.400 |

-0.010 |

10.562 |

-0.027 |

0.094 |

|

250 |

273.0 |

+1.60 |

-0.79 |

18.14 |

|

±0.38 |

10.16 |

-0.25 |

268.28 |

-0.69 |

2.39 |

|

12 |

12.750 |

+0.063 |

-0.031 |

0.714 |

|

±0.015 |

0.400 |

-0.010 |

12.531 |

-0.030 |

0.109 |

|

300 |

323.9 |

+1.60 |

-0.79 |

18.14 |

±0.38 |

10.16 |

-0.25 |

318.29 |

-0.76 |

2.77 |

|

1.EP cut-grooves are for plastic coated or cement lined pipe to be connected with Shurjoint XH-70EP couplings only. Any coating applied to the gasket seat (A) and gasket width (B) should not exceed 0.25mm (0.010”) thick. Do not roll groove pipe, which can damage the coating or lining and or create flared pipe ends.

2.Always use plain-end square cut pipe. Do not use beveled end pipe.

3.Always use an EP gasket with a XH-70EP coupling. Do not use a standard gasket.

4.The gasket seating area shall be free from deep scores, marks, or ridges that could prevent a positive seal.

General Notes:

ASME/ANSI Pressure-Temperature Rating is provided as an aid in selecting a proper coupling to incorporate with other piping components (valves, flanges, and etc.) that are used in the same system and carry the ASME/ANSI rating. Select a Class 150 coupling to incorporate with Class 150 valves and flanges.

Maximum Working Pressure (CWP) listed is the maximum cold water pressure for general piping services tested to ASTM F1476 and or AWWA C606 methods. Figures listed are based on roll- or cut-grooved standard wall carbon steel pipe. For other pipe schedules or pipe materials, contact Shurjoint for additional information.

Max. End Load is calculated based on the maximum working pressure (CWP).

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

C-09-2/3 Rev.K 20130218

XH-70EP

C-09

Job Name: |

System No. |

|

Location: |

Contractor: |

|

Approved: |

Date: |

Engineer: |

|

Approved: |

Date: |

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint products previously subsequently sold.

C-09-3/3 Rev.K 20130218

Trade Index Links