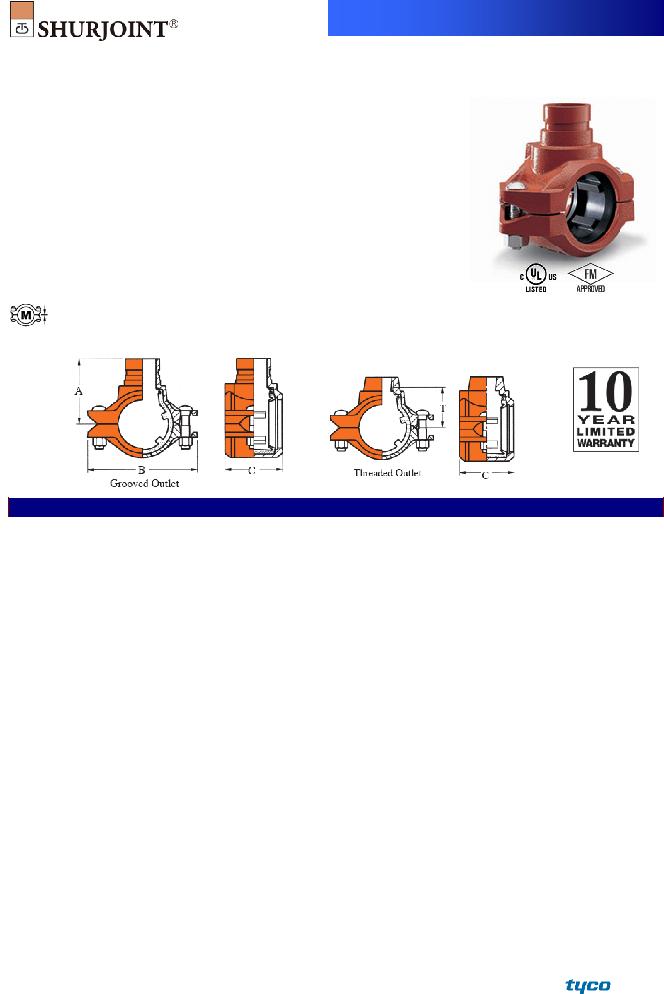

MODEL C-7 OUTLET COUPLING

The Model C-7 Outlet Coupling combines the features of a coupling and a reducing outlet. The C-7 is a joining device with an integral reducing outlet, eliminating the need for a mechanical tee or a reducing tee and couplings. The C-7 is available with grooved, male threaded or female threaded outlets. The C-7 coupling is recommended for fire sprinkler services and other applications up to 300 psi (20 Bar) depending on the size and schedule of pipe being used. The C-7 can be used for dry pipe systems or vacuum services up to -10 inHg or 254 mmHg which may occur when the system is drained. All Model C-7 couplings are comprised of an upper and lower ductile iron housings segment, EPDM rubber gasket and plated track bolts & nuts. Housings segments are supplied with our standard painted finishes, i.e. orange or RAL3000 red. Optional finishes such as hot dipped zinc galvanized and custom epoxy coatings are available.

C-7 couplings should always be installed so that the coupling bolt pads make metal to metal contact.

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet B-42 or visit SHURJOINT website, www.shurjoint.com for details or contact your SHURJOINT Representative.

Full warranty terms can be found on www.shurjoint.com

Model C-7 Outlet Coupling

|

Nominal Size |

Max. |

ASME/ANSI |

|

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working |

Axial |

End |

|

|

|

|

|

|

|

|

|

Outlet |

Pressure Class |

|

Dimensions |

|

|

|

Run |

|

Pressure |

Displace- |

Load |

|

|

Bolt |

|

|

|

Rating^ |

|

|

|

|

|

|

FPT |

Gr / MPT |

T** |

A |

|

B |

C |

|

Pipe |

(CWP)* |

@100oF/@38oC |

ment |

(CWP) |

|

Size |

Weight |

in |

in |

in |

PSI |

PSI |

in |

Lbs |

in |

in |

|

in |

in |

in |

Lbs |

mm |

mm |

mm |

Bar |

Nom. Class |

mm |

KN |

mm |

mm |

|

mm |

mm |

mm |

Kgs |

|

½ |

--- |

500 |

300 |

0.81~0.88 |

|

2.06 |

--- |

|

4.50 |

2.75 |

|

2.6 |

1½ |

15 |

--- |

35 |

150 |

20~22 |

1050 |

52 |

--- |

|

114.3 |

70.0 |

⅜ x 2⅛ |

1.2 |

¾ |

--- |

500 |

300 |

0.81~0.88 |

2.06 |

--- |

|

4.50 |

2.75 |

2.6 |

40 |

20 |

--- |

35 |

150 |

20~22 |

4.7 |

52 |

--- |

|

114.3 |

70.0 |

M10 x 55 |

1.2 |

|

1 |

--- |

500 |

300 |

0.81~0.88 |

|

1.94 |

--- |

|

4.50 |

2.75 |

|

2.9 |

|

25 |

--- |

35 |

150 |

20~22 |

|

49 |

--- |

|

114.3 |

70.0 |

|

1.3 |

|

½ |

--- |

500 |

300 |

0.81~0.88 |

|

2.32 |

--- |

|

5.00 |

2.75 |

|

3.1 |

2 |

15 |

--- |

35 |

150 |

20~22 |

2180 |

59 |

--- |

|

127.0 |

70.0 |

⅜ x 2⅛ |

1.4 |

¾ |

--- |

500 |

300 |

0.81~0.88 |

2.32 |

--- |

|

5.00 |

2.75 |

3.1 |

50 |

20 |

--- |

35 |

150 |

20~22 |

9.7 |

59 |

--- |

|

127.0 |

70.0 |

M10 x 55 |

1.4 |

|

1 |

1 |

500 |

300 |

0.81~0.88 |

|

2.20 |

3.50 |

|

5.00 |

2.75 |

|

3.3 |

|

25 |

33.4 |

35 |

150 |

20~22 |

|

56 |

89.0 |

|

127.0 |

70.0 |

|

1.5 |

|

½ |

--- |

500 |

300 |

1.25~1.50 |

|

2.20 |

--- |

|

6.33 |

3.25 |

|

4.8 |

|

15 |

--- |

35 |

150 |

32~38 |

|

56 |

--- |

|

161.0 |

83.0 |

|

2.2 |

|

¾ |

--- |

500 |

300 |

1.25~1.50 |

|

2.56 |

--- |

|

6.33 |

3.25 |

|

4.6 |

2½ |

20 |

--- |

35 |

150 |

32~38 |

3200 |

65 |

--- |

|

161.0 |

83.0 |

½ x 2⅜ |

2.1 |

1 |

--- |

500 |

300 |

1.25~1.50 |

2.44 |

--- |

|

6.33 |

3.25 |

4.4 |

65 |

25 |

--- |

35 |

150 |

32~38 |

14.2 |

62 |

--- |

|

161.0 |

83.0 |

M12 x 60 |

2.0 |

|

1¼ |

1¼ |

500 |

300 |

1.25~1.50 |

|

2.36 |

3.70 |

|

6.33 |

3.25 |

|

5.1 |

|

32 |

42.2 |

35 |

150 |

32~38 |

|

60 |

94.0 |

|

161.0 |

83.0 |

|

2.3 |

|

--- |

1½ |

500 |

300 |

1.25~1.50 |

|

--- |

3.70 |

|

6.33 |

3.25 |

|

5.9 |

|

--- |

48.3 |

35 |

150 |

32~38 |

|

--- |

94.0 |

|

161.0 |

83.0 |

|

2.4 |

|

¾ |

--- |

500 |

300 |

1.25~1.50 |

|

2.83 |

--- |

|

6.87 |

3.25 |

|

5.9 |

|

20 |

--- |

35 |

150 |

32~38 |

|

72 |

--- |

|

175.0 |

83.0 |

|

2.7 |

3 |

1 |

1 |

500 |

300 |

1.25~1.50 |

4750 |

2.75 |

4.00 |

|

6.87 |

3.25 |

½ x 3 |

6.2 |

25 |

33.4 |

35 |

150 |

32~38 |

70 |

102.0 |

|

175.0 |

83.0 |

2.8 |

80 |

1¼ |

1¼ |

500 |

300 |

1.25~1.50 |

21.0 |

2.75 |

4.00 |

|

6.87 |

3.25 |

M12 x 75 |

6.2 |

|

32 |

42.2 |

35 |

150 |

32~38 |

|

70 |

102.0 |

|

175.0 |

83.0 |

|

2.8 |

|

1½ |

1½ |

500 |

300 |

1.25~1.50 |

|

2.75 |

4.00 |

|

6.87 |

3.25 |

|

6.4 |

|

40 |

48.3 |

35 |

150 |

32~38 |

|

70 |

102.0 |

|

175.0 |

83.0 |

|

2.9 |

C-10-1/4 |

Rev.M |

20130220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C-7 |

|

|

|

|

|

|

C-10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

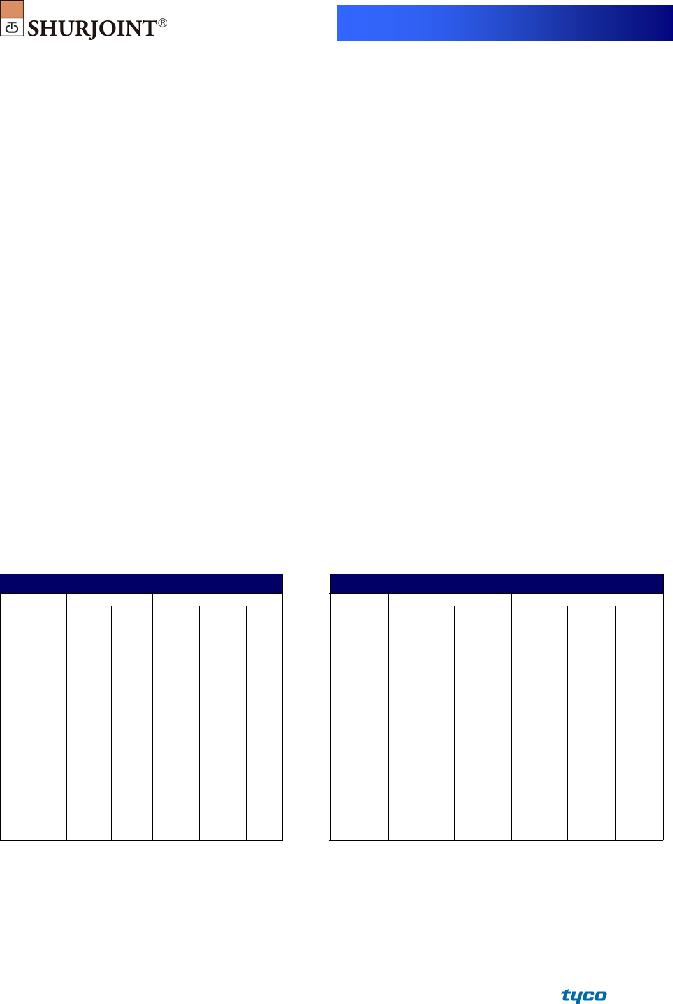

Model C-7 Outlet Coupling |

|

|

|

|

|

|

|

|

Nominal Size |

Max. |

|

ASME/ANSI |

|

|

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working |

|

Axial |

End |

|

|

|

|

|

|

|

|

|

|

|

Outlet |

|

Pressure Class |

|

|

Dimensions |

|

|

|

|

Run |

|

Pressure |

|

Displace- |

Load |

|

|

|

|

Bolt |

|

|

|

|

|

Rating^ |

|

|

|

|

|

|

|

|

|

FPT |

Gr / MPT |

|

|

T** |

A |

|

B |

C |

|

|

Pipe |

(CWP)* |

@100oF/@38oC |

ment |

(CWP) |

|

Size |

Weight |

|

in |

in |

in |

PSI |

|

PSI |

in |

|

Lbs |

|

in |

|

in |

|

in |

in |

in |

Lbs |

|

mm |

mm |

mm |

Bar |

|

Nom. Class |

mm |

|

KN |

|

mm |

|

mm |

|

mm |

mm |

mm |

Kgs |

|

|

¾ |

--- |

500 |

|

300 |

1.63~1.81 |

|

|

|

3.70 |

|

--- |

|

8.31 |

3.66 |

|

9.2 |

|

|

20 |

--- |

35 |

|

150 |

41~46 |

|

|

|

94 |

|

--- |

|

211.0 |

93.0 |

|

4.2 |

|

4 |

1 |

1 |

500 |

|

300 |

1.63~1.81 |

|

7840 |

|

3.58 |

|

4.88 |

|

8.31 |

3.66 |

⅝ x 3½ |

9.5 |

|

25 |

33.4 |

35 |

|

150 |

41~46 |

|

|

91 |

|

124.0 |

|

211.0 |

93.0 |

4.3 |

|

100 |

1½ |

1½ |

500 |

|

300 |

1.63~1.81 |

|

34.9 |

|

3.31 |

|

4.88 |

|

8.31 |

3.66 |

M16 x 90 |

9.5 |

|

|

40 |

48.3 |

35 |

|

150 |

41~46 |

|

|

|

84 |

|

124.0 |

|

211.0 |

93.0 |

|

4.3 |

|

|

2 |

2 |

500 |

|

300 |

1.63~1.81 |

|

|

|

3.50 |

|

4.88 |

|

8.31 |

3.66 |

|

9.9 |

|

|

50 |

60.3 |

35 |

|

150 |

41~46 |

|

|

|

89 |

|

124.0 |

|

211.0 |

93.0 |

|

4.5 |

|

|

¾ |

--- |

400 |

|

300 |

1.63~1.81 |

|

|

|

4.76 |

|

--- |

|

10.86 |

3.70 |

|

13.2 |

|

|

20 |

--- |

28 |

|

150 |

41~46 |

|

|

|

121 |

|

--- |

|

276.0 |

94.0 |

|

6.0 |

|

|

1 |

--- |

400 |

|

300 |

1.63~1.81 |

|

|

|

4.76 |

|

--- |

|

10.86 |

3.70 |

⅝ x 3½ |

13.2 |

|

6 |

25 |

--- |

28 |

|

150 |

41~46 |

|

14000 |

|

121 |

|

--- |

|

276.0 |

94.0 |

6.0 |

|

1½ |

1½ |

400 |

|

300 |

1.63~1.81 |

|

|

4.76 |

|

6.06 |

|

10.86 |

3.70 |

M16 x 90 |

13.6 |

|

150 |

40 |

48.3 |

28 |

|

150 |

41~46 |

|

62.3 |

|

121 |

|

154.0 |

|

276.0 |

94.0 |

|

6.2 |

|

|

2 |

2 |

400 |

|

300 |

1.63~1.81 |

|

|

|

4.40 |

|

6.06 |

|

10.86 |

3.70 |

|

14.3 |

|

|

50 |

60.3 |

28 |

|

150 |

41~46 |

|

|

|

111 |

|

154.0 |

|

276.0 |

94.0 |

|

6.5 |

|

|

--- |

2½ |

400 |

|

300 |

1.63~1.81 |

|

|

|

--- |

|

6.00 |

|

11.04 |

4.09 |

¾ x 4¾ |

18.7 |

|

|

--- |

76.1 |

28 |

|

150 |

41~46 |

|

|

|

--- |

|

152.5 |

|

280.5 |

104.0 |

M20 x 120 |

8.5 |

|

FPT: Female threaded outlet |

Gr: Grooved |

outlet |

MPT: Male |

threaded outlet. |

|

|

|

|

|

|

|

|

|

|

|

**T: Center of run pipe to end of outlet pipe (dimensions approximate). Female threaded outlet only.

*Working pressure is based on roll grooved standard wall carbon steel pipe.

^The ASME/ANSI pressure class rating is not the design or maximum pressure rating, rather is provided for those that are accustomed to specifying or using ASME/ANSI

pressure class rated components such as flange, valves, etc.

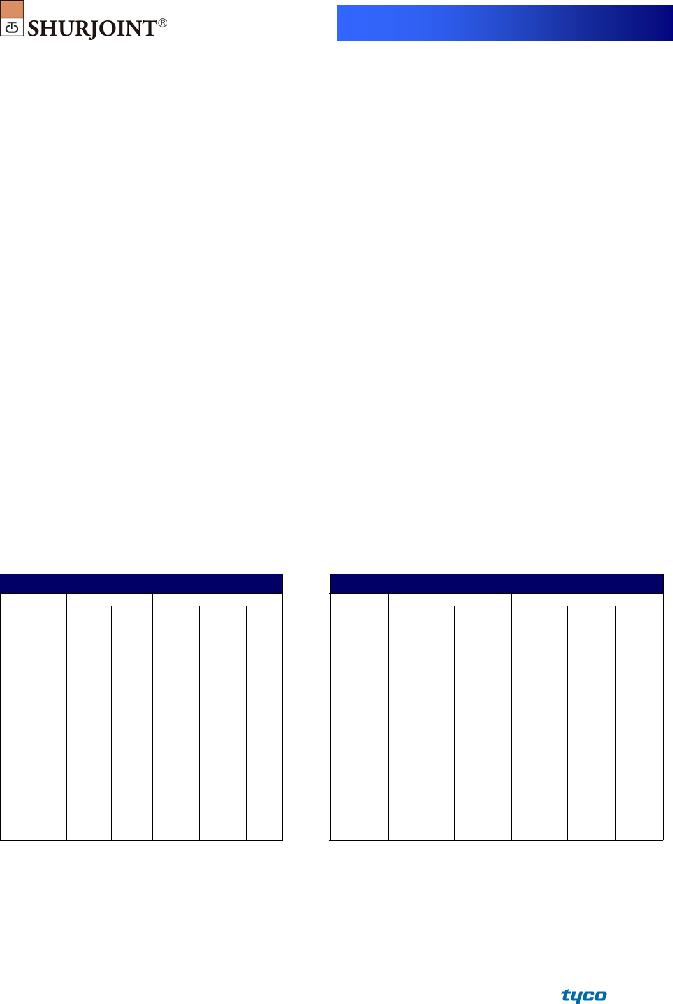

Performance Data

The following tables show the maximum working pressures (CWP) of Shurjoint Model C-7 Outlet Coupling used on both carbon steel and stainless steel pipes. Shurjoint ductile iron couplings can be used in conjunction with stainless steel pipe in non-corrosive environment as the flow media does not come in direct contact with the coupling housings but rather only the gasket.

Unit: psi / Bar

Model C-7 on Carbon Steel Pipe

Nom. Size |

Cut-Grooved |

|

Roll-Grooved |

in / mm |

XS |

STD |

|

STD |

Sch. 10 |

|

Sch. 7 |

1½ x * |

500 |

500 |

500 |

350 |

300 |

40 x * |

35 |

35 |

|

35 |

24 |

|

20 |

2 x * |

500 |

500 |

500 |

350 |

300 |

50 x * |

35 |

35 |

|

35 |

24 |

|

20 |

2½ x * |

500 |

500 |

500 |

350 |

300 |

65 x * |

35 |

35 |

|

35 |

24 |

|

20 |

2½ x * |

500 |

500 |

500 |

350 |

300 |

65 x * |

35 |

35 |

|

35 |

24 |

|

20 |

3 x * |

500 |

500 |

500 |

350 |

300 |

80 x * |

35 |

35 |

|

35 |

24 |

|

20 |

4 x * |

500 |

500 |

500 |

350 |

300 |

100 x * |

35 |

35 |

|

35 |

24 |

|

20 |

6 x * |

400 |

400 |

400 |

350 |

300 |

150 x * |

28 |

28 |

|

28 |

24 |

|

20 |

6 x * |

400 |

400 |

400 |

350 |

300 |

150 x * |

28 |

28 |

|

28 |

24 |

|

20 |

* = all branch sizes, threaded and grooved

Unit: psi / Bar

Model C-7 on Stainless Steel Pipe

Nom. Size |

Cut-Grooved |

Roll-Grooved |

in / mm |

Sch. 80S |

Sch. 40S |

Sch. 40S |

Sch. 10S |

Sch. 5S |

1½ x * |

500 |

500 |

350 |

300 |

250 |

40 x * |

35 |

35 |

24 |

20 |

17 |

2 x * |

500 |

500 |

350 |

300 |

250 |

50 x * |

35 |

35 |

24 |

20 |

17 |

2½ x * |

500 |

500 |

350 |

300 |

250 |

65 x * |

35 |

35 |

24 |

20 |

17 |

2½ x * |

500 |

500 |

350 |

300 |

250 |

65 x * |

35 |

35 |

24 |

20 |

17 |

3 x * |

500 |

500 |

350 |

300 |

250 |

80 x * |

35 |

35 |

24 |

20 |

17 |

4 x * |

500 |

500 |

350 |

300 |

250 |

100 x * |

35 |

35 |

24 |

20 |

17 |

6 x * |

400 |

400 |

300 |

300 |

250 |

150 x * |

28 |

28 |

20 |

20 |

17 |

6 x * |

400 |

400 |

300 |

300 |

250 |

150 x * |

28 |

28 |

20 |

20 |

17 |

* = all branch sizes, threaded and grooved

General Notes:

ASME/ANSI Pressure-Temperature Rating is provided as an aid in selecting a proper coupling to incorporate with other piping components (valves, flanges, and etc.) that are used in the same system and carry the ASME/ANSI rating. Select a Class 150 coupling to incorporate with Class 150 valves and flanges.

Maximum Working Pressure (CWP) listed is the maximum cold water pressure for general piping services tested to ASTM F1476 and or AWWA C606 methods. Figures listed are based on roll- or cut-grooved standard wall carbon steel pipe. For other pipe schedules or pipe materials, contact Shurjoint for additional information.

Max. End Load is calculated based on the maximum working pressure (CWP).

Listed and or Approved Pressures are pressure ratings for fire protection systems, tested and approved by various approval bodies. Please always refer to the latest approval data posted on the Shurjoint website.

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Job Name: |

System No. |

|

Location: |

Contractor: |

|

Approved: |

Date: |

Engineer: |

|

Approved: |

Date: |

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint products previously subsequently sold.

C-10-4/4 Rev.M 20130220

Trade Index Links