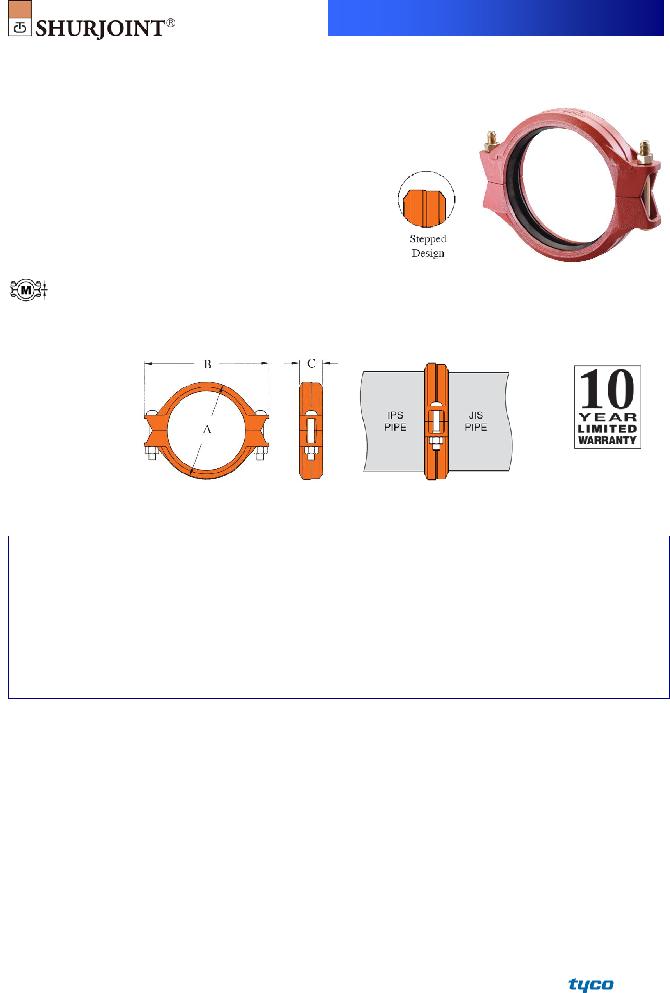

MODEL 7771-T IPS / JIS TRANSITION COUPLING

The Shurjoint Model 7771-T Transition Coupling provides a direct transition from IPS pipe sizes to JIS pipe sizes. Any combination of pipe, valves or fittings of different pipe OD's of nominal sizes 8" through 12" can be connected with a single coupling. As bolts and nuts are fastened until the bolt pads come to a metal-to-metal contact, the coupling provides a rigid and positive joint.

The stepped exterior design of the housings aids to avoid erroneous positioning of IPS and JIS sides of the housings.

7771-T couplings should always be installed so that the coupling bolt pads make metal to metal contact.

Full warranty terms can be found on www.shurjoint.com

|

|

|

|

Model |

7771-T IPS / JIS Transition Coupling |

|

|

|

|

|

|

|

|

|

ASME/ANSI |

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

Max. Working |

End |

|

|

|

|

|

|

|

|

|

|

Actual Pipe O.D. |

Pressure Class |

|

|

Dimension |

|

|

|

|

|

Nominal |

Pressure |

Rating^ |

Load |

Total Axial |

|

|

Bolt Size |

Weight |

|

|

Size |

IPS |

JIS |

(CWP)* |

@100oF/@38oC |

(CWP) |

Movement † |

A |

B |

C |

|

|

mm |

in |

in |

PSI |

PSI |

Lbs |

in |

in |

in |

|

in |

mm |

Lbs |

|

|

|

|

|

Nom. Class |

|

|

|

|

|

|

|

|

|

mm |

mm |

Bar |

kN |

mm |

mm |

mm |

|

mm |

Kgs |

|

|

|

|

|

|

|

200 JIS |

8.625 |

8.515 |

300 |

300 |

17520 |

0.13 |

10.20 |

13.19 |

|

2.50 |

M16 x 135 |

15.4 |

|

|

219.1 |

216.3 |

20 |

150 |

75.37 |

3.2 |

259 |

335 |

|

63 |

7.0 |

|

|

|

|

|

|

|

250 JIS |

10.750 |

10.528 |

300 |

300 |

27190 |

0.13 |

12.46 |

15.20 |

|

2.50 |

M20 x 120 |

19.8 |

|

|

273.0 |

267.4 |

20 |

150 |

117.01 |

3.2 |

316 |

386 |

|

63 |

9.0 |

|

|

|

|

|

|

|

300 JIS |

12.750 |

12.539 |

300 |

300 |

38280 |

0.13 |

14.45 |

17.64 |

|

2.50 |

M22 x 165 |

24.2 |

|

|

323.9 |

318.5 |

20 |

150 |

164.71 |

3.2 |

367 |

448 |

|

63 |

11.0 |

|

|

|

|

|

|

For 6” (168.3) x 6” (165.1), see Model 7706-T.

* Working Pressure is based on roll- or cut-grooved standard wall carbon steel pipe.

^The ASME/ANSI pressure class rating is not the design or maximum pressure rating, rather is provided for those that are accustomed to specifying or using ASME/ANSI pressure class rated components such as flange, valves, etc.

† Allowable Axial Displacement and Angular Movement (deflection) figures are for roll grooved standard steel pipe. Values for cut grooved pipe will be double that of roll grooved. These values are maximums; for design and installation purposes these figures should be reduced by: 50% for ¾” – 3½”; 25% for 4” and larger to compensate for jobsite conditions.

C-12-1/2 Rev.G 20130220

MATERIAL SPECIFICATIONS

• Housing:

Ductile Iron to ASTM A536, Gr. 65-45-12 and or ASTM A395, Gr. 65-45-15, min. tensile strength 65,000 psi (448 MPa).

• Surface Finish:

Standard painted finishes in orange or RAL3000 red.

Hot dip zinc galvanized (Option).

Epoxy Coatings in RAL3000 red or other colors (Option)

•Rubber Gasket:

Grade “E” EPDM (Color code: Green stripe) Good for cold & hot water up to +230oF (+110oC). Also good for services for water with acid, water with chlorine, deionized water, seawater and waste water, dilute acids, oil-free air and many chemicals.

Not recommended for petroleum oils, minerals oils, solvents and aromatic hydrocarbons.

Maximum Temperature Range: -30oF (-34oC) to +230oF (+110oC)*.

*EPDM gaskets for water services are not recommended for steam services unless couplings or components are accessible for frequent gasket replacement.

General Notes:

(Option) Grade “T” Nitrile (Color code: Orange stripe) Recommended for petroleum products, air with oil vapors, vegetable and mineral oils within the specified temperature range. Also good for water services under +150oF (+66oC).

Temperature range: -20 oF to +180 oF (-29 oC to +82 oC).

Do not use for HOT WATER above +150 oF (+66 oC) or HOT DRY AIR above +140 oF (+60 oC).

Other options: Grade “O” - Fluoroelastomer.

Grade “L” - Silicone.

For additional details contact Shurjoint.

• Bolts & Nuts:

Heat treated carbon manganese steel track bolts to ASTM A449-83a (or A183 Gr. 2), minimum tensile strength 110,000 psi (758 MPa), Zinc electroplated, with heavy-duty hexagonal nuts to ASTM A563.

ASME/ANSI Pressure-Temperature Rating is provided as an aid in selecting a proper coupling to incorporate with other piping components (valves, flanges, and etc.) that are used in the same system and carry the ASME/ANSI rating. Select a Class 150 coupling to incorporate with Class 150 valves and flanges.

Maximum Working Pressure (CWP) listed is the maximum cold water pressure for general piping services tested to ASTM F1476 and or AWWA C606 methods. Figures listed are based on roll- or cut-grooved standard wall carbon steel pipe. For other pipe schedules or pipe materials, contact Shurjoint for additional information.

Max. End Load is calculated based on the maximum working pressure (CWP).

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Job Name: |

System No. |

|

Location: |

Contractor: |

|

Approved: |

Date: |

Engineer: |

|

Approved: |

Date: |

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint products previously subsequently sold.

C-12-2/2 Rev.G 20130220

Trade Index Links