7707N |

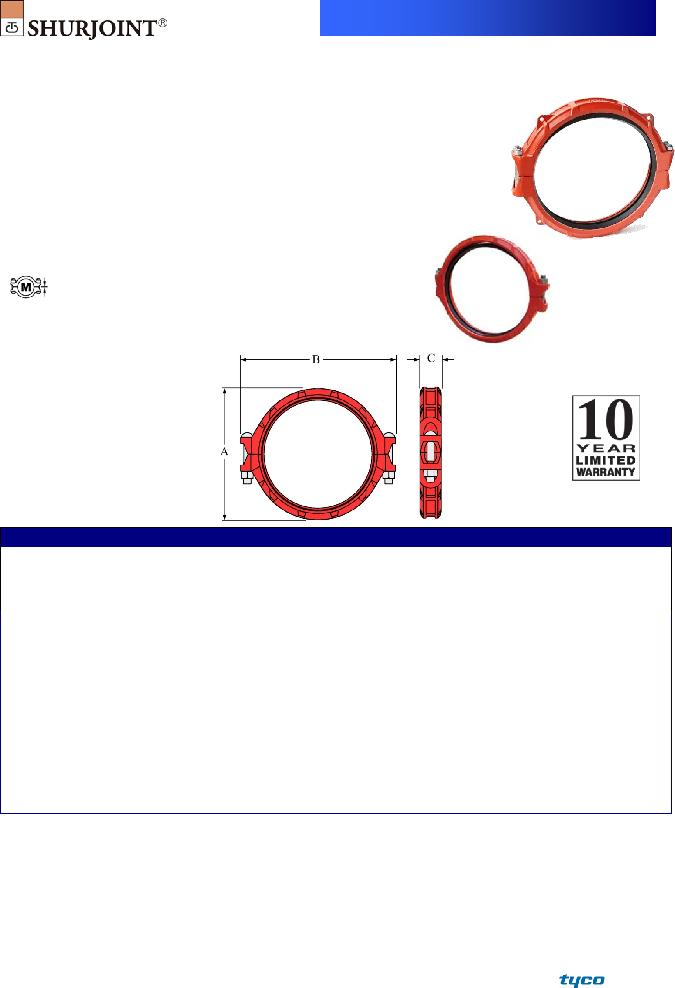

MODEL 7707N HEAVY DUTY FLEXIBLE COUPLING

The Model 7707N Heavy Duty Flexible Coupling is designed for use in a variety of general piping applications of moderate or high pressure services. The Model 7707N couplings feature flexibility that can deal with misalignment, distortion, thermal stress, vibration and noise and also resist seismic tremors. With the use of Model 7707N couplings you can even design a curved layout. See Typical application – Flexible Couplings on Shurjoint Data Sheet

The Model 7707N couplings sizes 14” – 26” (350 mm – 650 mm) are com- prised of two identical ductile iron housing segments, an EPDM rubber gasket and one or two bolts at each segment joint to ensure a positive connection and seal.

7707N couplings should always be installed so that the coupling bolt pads make metal to metal contact.

Size: 26”

Size: 14”~24”

Full warranty terms can be found on www.shurjoint.com

Model 7707N Heavy Duty Flexible Coupling

|

|

|

|

|

|

Angular |

|

|

|

|

|

|

||

|

|

Max. |

ASME/ANSI |

Max. |

|

Movement**† |

|

|

|

|

|

|

||

|

|

Working |

End |

Axial |

Degree |

|

|

|

|

|

|

|

||

|

|

Pressure Class |

|

|

Dimensions |

|

|

Bolt |

|

|||||

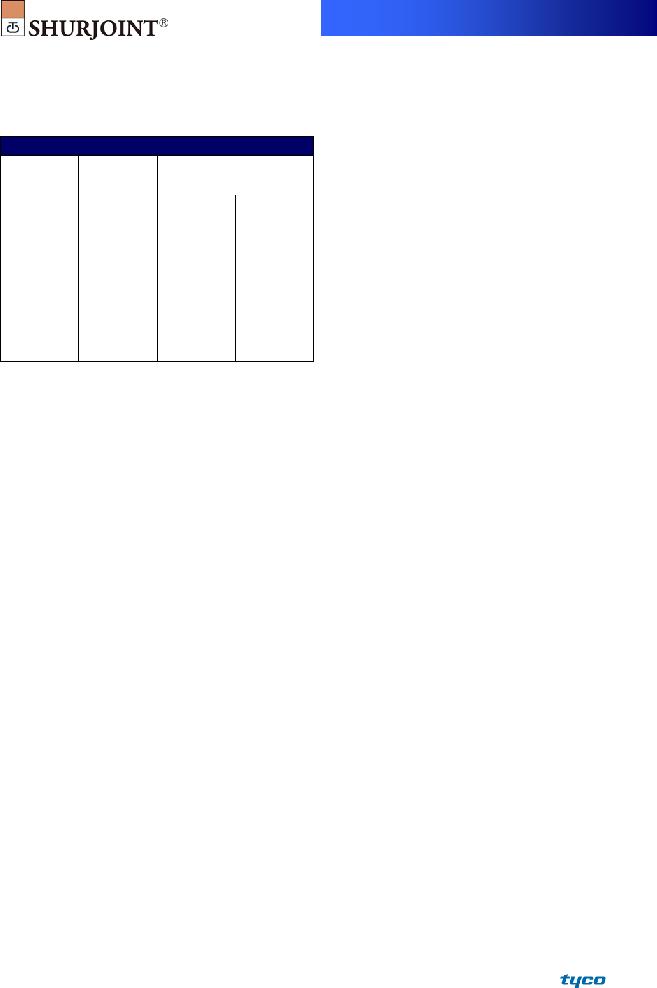

Nominal |

Pipe |

Pressure |

Load |

Displace- |

Per |

Per |

|

|

|

|

||||

Rating^ |

|

|

|

|

|

|

||||||||

A |

B |

C |

No |

Size |

Weight |

|||||||||

Size |

O.D. |

(CWP)* |

@100oF/@38oC |

(CWP) |

ment † |

Coupling |

Pipe |

|||||||

in |

in |

PSI |

PSI |

Lbs |

in |

(o) |

in / ft |

in |

in |

in |

|

in |

Lbs |

|

mm |

mm |

Bar |

Nom. Class |

kN |

mm |

|

mm / m |

mm |

mm |

mm |

|

|

Kgs |

|

14 |

14.00 |

300 |

300 |

46150 |

0.125 |

0o – 31’ |

0.06 |

16.23 |

18.85 |

2.95 |

2 |

⅞ x6½ |

34.5 |

|

350 |

355.6 |

20 |

150 |

198.53 |

3.2 |

4.5 |

412.0 |

479.0 |

75.0 |

15.7 |

||||

|

|

|

||||||||||||

16 |

16.00 |

300 |

300 |

60280 |

0.125 |

0o – 27’ |

0.05 |

18.23 |

21.53 |

2.95 |

2 |

1 x 6½ |

37.0 |

|

400 |

406.4 |

20 |

150 |

259.30 |

3.2 |

4.0 |

463.0 |

547.0 |

75.0 |

16.8 |

||||

|

|

|

||||||||||||

18 |

18.00 |

300 |

300 |

76300 |

0.125 |

0o – 24’ |

0.04 |

20.45 |

23.81 |

3.11 |

2 |

1 x 6½ |

47.1 |

|

450 |

457.2 |

20 |

150 |

327.89 |

3.2 |

3.5 |

520.0 |

605.0 |

79.0 |

22.3 |

||||

|

|

|

||||||||||||

20 |

20.00 |

300 |

300 |

94200 |

0.125 |

0o – 22’ |

0.04 |

22.48 |

25.82 |

3.11 |

2 |

1 x 6½ |

54.4 |

|

500 |

508.0 |

20 |

150 |

405.16 |

3.2 |

3.0 |

571.0 |

656.0 |

79.0 |

24.7 |

||||

|

|

|

||||||||||||

22 |

22.00 |

300 |

300 |

113980 |

0.125 |

0o – 19’ |

0.04 |

24.46 |

28.52 |

3.11 |

2 |

1⅛ x6½ |

63.0 |

|

550 |

558.8 |

20 |

150 |

490.60 |

3.2 |

3.0 |

621.4 |

724.6 |

79.0 |

28.6 |

||||

|

|

|

||||||||||||

24 |

24.00 |

300 |

300 |

135640 |

0.125 |

0o – 18’ |

0.03 |

26.55 |

30.70 |

3.11 |

2 |

1⅛ x6½ |

65.1 |

|

600 |

609.6 |

20 |

150 |

584.20 |

3.2 |

2.5 |

674.0 |

780.0 |

79.0 |

29.5 |

||||

|

|

|

||||||||||||

26 |

26.00 |

300 |

300 |

159190 |

0.125 |

0o – 17’ |

0.03 |

29.68 |

33.15 |

4.94 |

4 |

⅞ x9⅝ |

143.0 |

|

650 |

660.4 |

20 |

150 |

684.72 |

3.2 |

2.5 |

754.0 |

842.0 |

125.6 |

65.0 |

||||

|

|

|

||||||||||||

* Working pressure is based on

^ The ASME/ANSI pressure class rating is not the design or maximum pressure rating, rather is provided for those that are accustomed to specifying or using ASME/ANSI pressure class rated components such as flange, valves, etc.

† Allowable Axial Displacement and Angular Movement (deflection) figures are for roll grooved standard steel pipe. Values for cut grooved pipe will be double that of roll grooved. These values are maximums; for design and installation purposes these figures should be reduced by: 50% for ¾” – 3½”; 25% for 4” and larger to compensate for jobsite conditions.

** Deflection or angular movement is the maximum value that a coupling allows under no internal pressure.