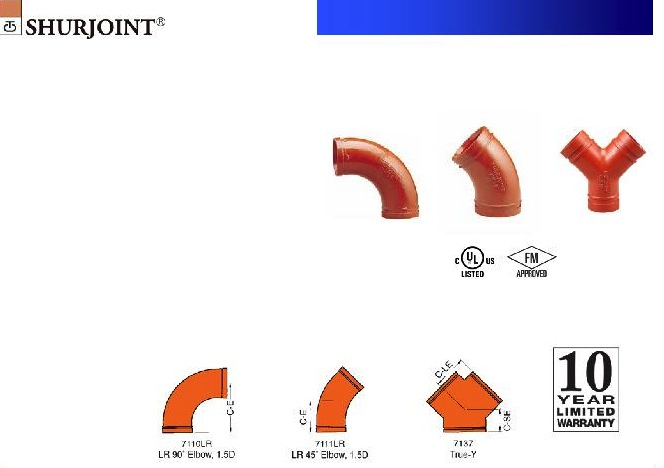

MODEL 7110LR 1.5D LONG RADIUS 90o ELBOW 7111LR 1.5D LONG RADIUS 45o ELBOW 7137

Shurjoint

ASTM A536 Gr.

Shurjoint standard fitting pressure ratings conform to the ratings of Model 7707 couplings.

7110LR |

7111LR |

7137 |

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet

|

|

|

|

|

|

|

|

Full |

warranty terms |

|

|

|

|

|

|

|

|

|

can |

be found on |

|

|

|

|

|

|

|

|

|

www.shurjoint.com |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Models 7110LR / 7111LR / 7137 |

|

|

|

|

||

|

Nominal Pipe |

Pipe |

|

#7110LR |

|

#7111LR |

|

#7137 |

|

|

|

Size |

O.D. |

1.5D LR 900 Elbows |

1.5D LR 450 Elbows |

|

|

|

|||

|

in |

in |

Lbs |

Lbs |

Lbs |

|

||||

|

mm |

mm |

in / mm |

Kgs |

in / mm |

Kgs |

in / mm |

in / mm |

Kgs |

|

2 |

2.375 |

4.38 |

2.4 |

2.75 |

1.8 |

3.25 |

2.75 |

2.5 |

|

|

50 |

60.3 |

111 |

1.1 |

70 |

0.8 |

83 |

70 |

1.1 |

|

|

2½ |

2.875 |

5.00 |

4.0 |

3.00 |

3.1 |

3.75 |

3.00 |

3.8 |

|

|

65 |

73.0 |

127 |

1.8 |

76 |

1.4 |

95 |

76 |

1.7 |

|

|

|

76.1 mm |

3.000 |

5.00 |

4.0 |

3.00 |

3.2 |

3.75 |

3.00 |

4.0 |

|

|

76.1 |

127 |

1.8 |

76 |

1.5 |

95 |

76 |

1.8 |

|

|

|

|

|

||||||||

3 |

3.500 |

5.88 |

5.8 |

3.38 |

4.0 |

4.25 |

3.25 |

5.5 |

|

|

80 |

88.9 |

149 |

2.6 |

86 |

1.8 |

108 |

83 |

2.5 |

|

|

4 |

4.500 |

7.50 |

10.3 |

4.00 |

7.7 |

5.00 |

3.75 |

10.4 |

|

|

100 |

114.3 |

191 |

4.7 |

102 |

3.5 |

127 |

95 |

4.7 |

|

|

|

139.7 mm |

5.500 |

9.50 |

18.1 |

5.00 |

10.1 |

5.50 |

4.00 |

15.0 |

|

|

139.7 |

241 |

8.2 |

127 |

4.6 |

140 |

102 |

6.8 |

|

|

|

|

|

||||||||

5 |

5.563 |

9.50 |

18.1 |

5.00 |

10.1 |

5.50 |

4.00 |

11.6 |

|

|

125 |

141.3 |

241 |

8.2 |

127 |

4.6 |

140 |

102 |

5.3 |

|

|

|

165.1 mm |

6.500 |

10.75 |

25.3 |

5.50 |

18.0 |

6.50 |

4.50 |

19.6 |

|

|

165.1 |

273 |

11.5 |

140 |

8.2 |

165 |

114 |

8.9 |

|

|

|

|

|

||||||||

6 |

6.625 |

10.75 |

25.3 |

5.50 |

18.0 |

6.50 |

4.50 |

19.6 |

|

|

150 |

168.3 |

273 |

11.5 |

140 |

8.2 |

165 |

114 |

8.9 |

|

|

8 |

8.625 |

14.25 |

50.7 |

7.25 |

35.3 |

7.75 |

6.00 |

34.3 |

|

|

200 |

219.1 |

362 |

23.0 |

184 |

16.0 |

197 |

152 |

15.6 |

|

|

10 |

10.750 |

17.25 |

73.0 |

8.50 |

78.6 |

9.00 |

6.50 |

56.2 |

|

|

250 |

273.0 |

438 |

42.2 |

216 |

36.1 |

229 |

165 |

25.5 |

|

|

12 |

12.750 |

20.50 |

157.6 |

10.00 |

73.9 |

10.00 |

7.00 |

79.4 |

|

|

300 |

323.9 |

521 |

71.5 |

254 |

33.5 |

254 |

178 |

36.0 |

|

|