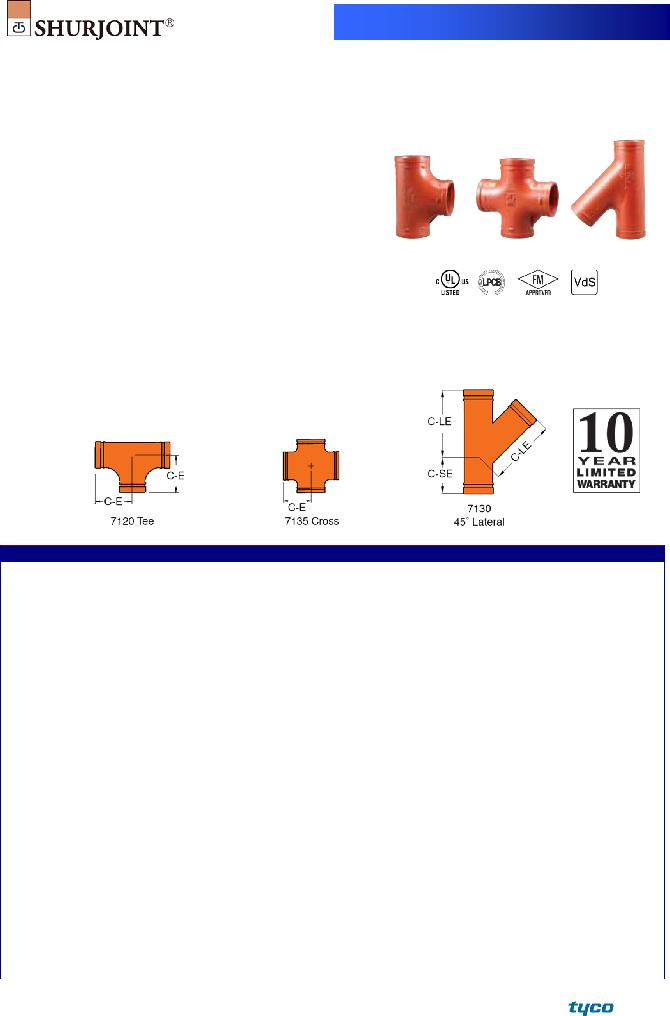

MODELS 7120 TEE 7135 CROSS

7130 45o LATERAL

Shurjoint

For sizes larger than 14” (350 mm) are fabricated from standard weight (0.375” or 9.5 mm) carbon steel pipe to ASTM A234 GR. WPB or segmentally welded with carbon steel of the same or equivalent grade.

Shurjoint standard fitting pressure ratings conform to the ratings of Model 7707 couplings.

7120 |

7135 |

7130 |

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet

Full warranty terms can be found on www.shurjoint.com

Model 7120 TEE / 7135 CROSS / 7130 45° LATERAL

|

Nominal Pipe |

Pipe |

|

#7120 |

#7135 |

|

|

#7130 |

|

|

|

|

|

Size |

O.D. |

|

Tee |

Cross |

|

|

45o Lateral |

|

|

||

|

in |

in |

Lbs |

|

Lbs |

|

Lbs |

|

||||

|

mm |

mm |

in / mm |

Kgs |

in / mm |

|

Kgs |

in / mm |

in / mm |

|

Kgs |

|

|

1 |

1.315 |

2.25 |

0.9 |

2.25 |

|

|

|

||||

25 |

33.4 |

57 |

0.4 |

57 |

|

|

|

|||||

1¼ |

1.660 |

2.75 |

1.5 |

2.75 |

|

|

|

|||||

32 |

42.2 |

70 |

0.7 |

70 |

|

|

|

|||||

1½ |

1.900 |

2.75 |

2.0 |

2.75 |

|

|

|

|||||

40 |

48.3 |

70 |

0.9 |

70 |

|

|

|

|||||

2 |

2.375 |

3.25 |

2.9 |

3.25 |

|

2.7 |

7.00 |

2.75 |

|

4.4 |

|

|

50 |

60.3 |

83 |

1.3 |

83 |

|

1.2 |

178 |

70 |

|

2.0 |

|

|

2½ |

2.875 |

3.75 |

4.8 |

3.75 |

|

6.6 |

7.75 |

3.00 |

|

6.2 |

|

|

65 |

73.0 |

95 |

2.2 |

95 |

|

3.0 |

197 |

76 |

|

2.8 |

|

|

|

76.1 mm |

3.000 |

3.75 |

5.1 |

3.75 |

|

6.6 |

7.75 |

3.00 |

|

6.2 |

|

|

76.1 |

95 |

2.3 |

95 |

|

3.0 |

197 |

76 |

|

2.8 |

|

|

|

|

|

|

|

||||||||

3 |

3.500 |

4.25 |

6.8 |

4.25 |

|

6.8 |

8.50 |

3.25 |

|

9.2 |

|

|

80 |

88.9 |

108 |

3.1 |

108 |

|

3.1 |

216 |

83 |

|

4.2 |

|

|

4 |

4.500 |

5.00 |

9.9 |

5.00 |

|

11.5 |

10.50 |

3.75 |

|

17.6 |

|

|

100 |

114.3 |

127 |

4.5 |

127 |

|

5.2 |

267 |

95 |

|

8.0 |

|

|

|

108.0 mm |

4.250 |

5.00 |

9.0 |

|

|

|

|||||

|

108.0 |

127 |

4.1 |

|

|

|

||||||

|

|

|

|

|

||||||||

|

133.0 mm |

5.250 |

5.50 |

13.2 |

|

|

|

|||||

|

133.0 |

140 |

6.0 |

|

|

|

||||||

|

|

|

|

|

||||||||

|

139.7 mm |

5.500 |

5.50 |

14.3 |

5.50 |

|

13.0 |

12.50 |

4.00 |

|

27.5 |

|

|

139.7 |

140 |

6.5 |

140 |

|

5.9 |

318 |

102 |

|

12.5 |

|

|

|

|

|

|

|

||||||||

5 |

5.563 |

5.50 |

14.3 |

5.50 |

|

13.0 |

12.50 |

4.00 |

|

27.5 |

|

|

125 |

141.3 |

140 |

6.5 |

140 |

|

5.9 |

318 |

102 |

|

12.5 |

|

|

6 |

6.250 |

6.50 |

18.9 |

|

|

|

||||||

150 |

159.0 |

165 |

8.6 |

|

|

|

||||||

|

165.1 mm |

6.500 |

6.50 |

21.7 |

6.50 |

|

32.0 |

14.00 |

4.50 |

|

40.7 |

|

|

165.1 |

165 |

9.9 |

165 |

|

14.5 |

356 |

114 |

|

18.5 |

|

|

|

|

|

|

|

||||||||

6 |

6.625 |

6.50 |

22.0 |

6.50 |

|

32.0 |

14.00 |

4.50 |

|

40.7 |

|

|

150 |

168.3 |

165 |

10.0 |

165 |

|

14.5 |

356 |

114 |

|

18.5 |

|

|

8 |

8.625 |

7.75 |

44.0 |

7.75 |

|

44.1 |

18.00 |

6.00 |

|

70.4 |

|

|

200 |

219.1 |

197 |

20.0 |

197 |

|

20.0 |

457 |

152 |

|

32.0 |

|

|

10 |

10.750 |

9.00 |

68.2 |

|

20.50 |

6.50 |

|

138.9 |

|

|||

250 |

273.0 |

229 |

31.0 |

|

521 |

165 |

|

63.0 |

|

|||

|

20130509 |

|

|

|

|

|

|

|

|

|

|

|