Rubber Lined Fittings |

RUBBER LINED FITTINGS

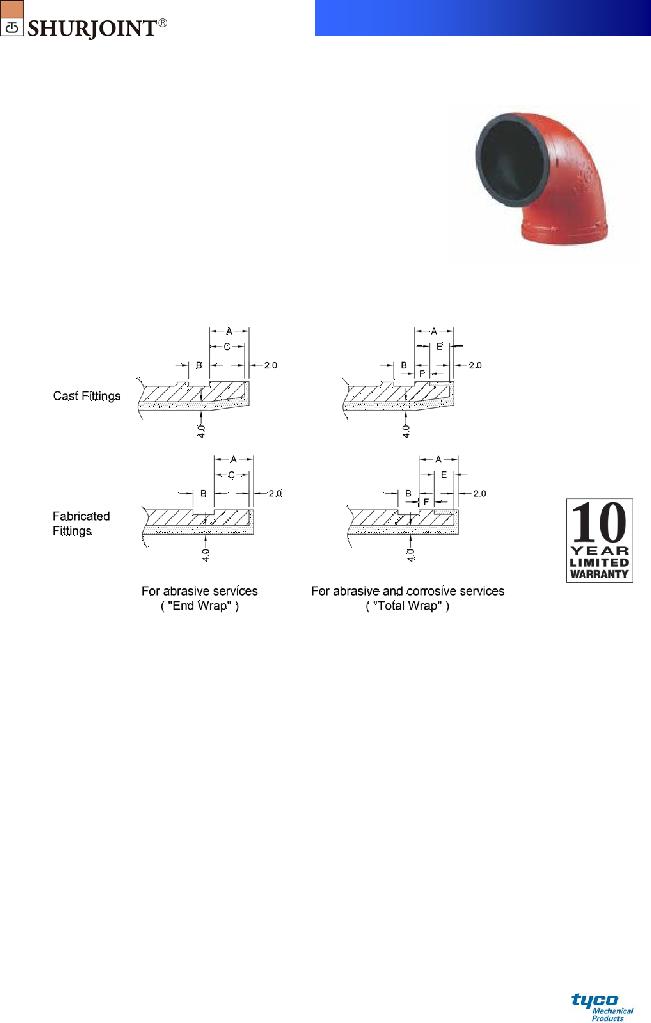

Shurjoint grooved end fittings are also available with rubber lining for abrasive services. The lining is available covering the interior and ends of the fittings for abrasive services ( "End Wrap" ) or the lining can be further wrapped around the seating area of the fittings for abrasive and corrosive service applications ( "Total Wrap" ). All groove dimensions conform to ANSI / AWWA C606 (latest version) and or ISO/FDIS

Shurjoint standard fitting pressure ratings conform to the ratings of Model 7707 couplings.

|

|

|

|

|

|

|

|

Full warranty terms |

|

|

|

|

|

|

|

|

|

can be found on |

|

|

|

|

|

|

|

|

|

www.shurjoint.com |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rubber Lined Fittings |

|

|

|

|

|

|

Nominal Pipe |

Pipe |

A |

B |

C |

E |

F |

Rubber Lining |

|

|

Size |

OD |

±0.8 / ±0.03 |

±0.8 / ±0.03 |

Thickness |

|

|||

|

|

|

|

|

|||||

|

in |

in |

in |

in |

in |

in |

in |

in |

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

2 |

2.375 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.16 |

|

|

50 |

60.3 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

4.0 |

|

|

2½ |

2.875 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.16 |

|

|

65 |

73.0 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

4.0 |

|

|

|

76.1 mm |

3.000 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.16 |

|

|

76.1 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

4.0 |

|

|

|

|

|

|||||||

3 |

3.500 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.16 |

|

|

80 |

88.9 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

4.0 |

|

|

4 |

4.500 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.24 |

|

|

100 |

114.3 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

6.0 |

|

|

|

139.7 mm |

5.500 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.24 |

|

|

139.7 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

6.0 |

|

|

|

|

|

|||||||

5 |

5.563 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.24 |

|

|

125 |

141.3 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

6.0 |

|

|

|

165.1 mm |

6.500 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.24 |

|

|

165.1 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

6.0 |

|

|

|

|

|

|||||||

6 |

6.625 |

0.63 |

0.375 |

0.55 |

0.35 |

0.2 |

0.24 |

|

|

150 |

168.3 |

15.9 |

9.5 |

13.9 |

9.0 |

4.9 |

6.0 |

|

|

8 |

8.625 |

0.75 |

0.44 |

0.67 |

0.35 |

0.32 |

0.24 |

|

|

200 |

219.1 |

19.05 |

11.13 |

17.05 |

9.0 |

8.1 |

6.0 |

|

|

10 |

10.750 |

0.75 |

0.50 |

0.67 |

0.35 |

0.32 |

0.24 |

|

|

250 |

273.0 |

19.05 |

12.70 |

17.05 |

9.0 |

8.1 |

6.0 |

|

|

12 |

12.750 |

0.75 |

0.50 |

0.67 |

0.35 |

0.32 |

0.24 |

|

|

300 |

323.9 |

19.05 |

12.70 |

17.05 |

9.0 |

8.1 |

6.0 |

|

|

20131016 |

|

|

|

|

|

|

|

||