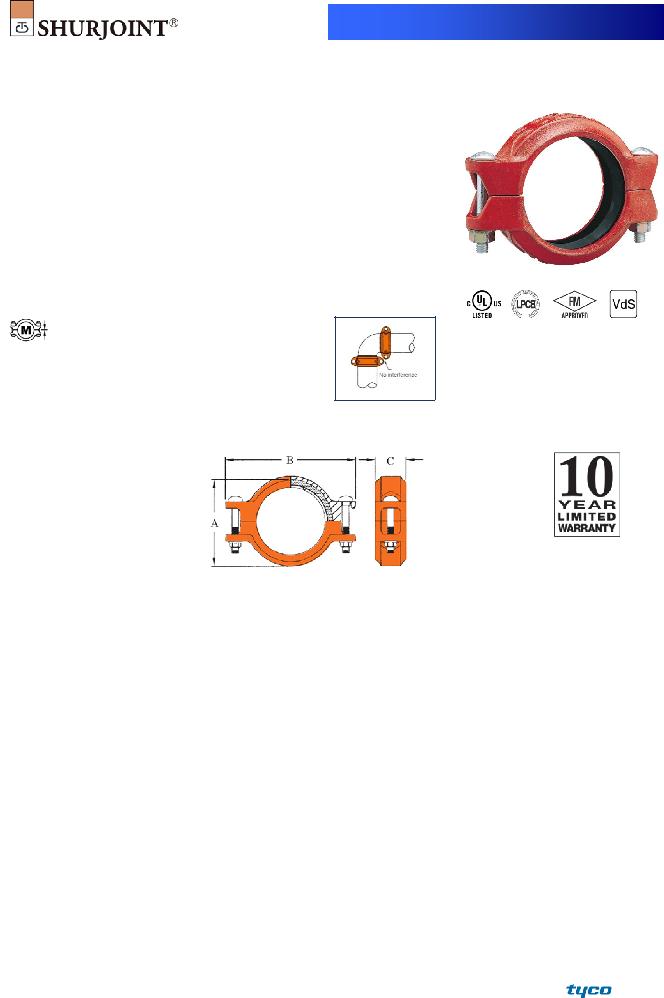

MODEL

- T&G Design -

The Shurjoint Model

The Model

No need to worry about bold pad interference as the Model

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full warranty terms |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

can be found |

on |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

www.shurjoint.com |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|||||||

|

Nominal |

Pipe |

Max. |

ASME/ANSI |

Max |

|

Axial |

|

|

Dimension |

|

|

|

Bolt |

|

|

|||||

|

Working |

Pressure Class |

End |

|

|

|

|

|

|

|

|

||||||||||

|

Size |

OD |

Pressure |

Rating^ |

Load |

|

Displacement |

|

|

|

|

|

|

|

|

Size |

Weight |

|

|||

|

|

A |

|

B |

C |

|

|

||||||||||||||

|

|

|

|

(CWP)* |

@100oF/@38oC |

(CWP) |

|

|

|

|

|

|

|

|

|

|

|||||

|

in |

in |

|

PSI |

PSI |

|

Lbs |

|

in |

|

|

in |

|

in |

|

in |

|

|

in |

Lbs |

|

|

mm |

mm |

|

Bar |

Nom. class |

|

kN |

|

mm |

|

|

mm |

|

mm |

|

mm |

|

|

mm |

Kgs |

|

|

1¼ |

1.660 |

|

500 |

300 |

|

1080 |

0~0.06 |

|

2.56 |

4.33 |

|

1.77 |

|

|

⅜ x 1¾ |

1.3 |

|

|||

32 |

42.2 |

|

34.5 |

150 |

|

4.82 |

0~1.6 |

|

65 |

110 |

|

45 |

|

|

M10 x 45 |

0.6 |

|

||||

1½ |

1.900 |

|

500 |

300 |

|

1410 |

0~0.06 |

|

2.80 |

4.45 |

|

1.77 |

|

|

⅜ x 2⅛ |

1.3 |

|

||||

40 |

48.3 |

|

34.5 |

150 |

|

6.32 |

0~1.6 |

|

71 |

113 |

|

45 |

|

|

M10 x 55 |

0.6 |

|

||||

2 |

2.375 |

|

500 |

300 |

|

2210 |

0~0.06 |

|

3.27 |

4.88 |

|

1.77 |

|

|

⅜ x 2⅛ |

1.5 |

|

||||

50 |

60.3 |

|

34.5 |

150 |

|

9.85 |

0~1.6 |

|

83 |

124 |

|

45 |

|

|

M10 x 55 |

0.7 |

|

||||

2½ |

2.875 |

|

500 |

300 |

|

3240 |

0~0.06 |

|

3.86 |

5.39 |

|

1.77 |

|

|

⅜ x 2⅛ |

1.8 |

|

||||

65 |

73.0 |

|

34.5 |

150 |

|

14.43 |

0~1.6 |

|

98 |

137 |

|

45 |

|

|

M10 x 55 |

0.8 |

|

||||

|

76.1 mm |

3.000 |

|

500 |

300 |

|

3530 |

0~0.06 |

|

4.00 |

5.51 |

|

1.77 |

|

|

⅜ x 2⅛ |

1.8 |

|

|||

|

76.1 |

|

34.5 |

150 |

|

15.68 |

0~1.6 |

|

102 |

140 |

|

45 |

|

|

M10 x 55 |

0.8 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

3 |

3.500 |

|

500 |

300 |

|

4800 |

0~0.06 |

|

4.50 |

5.94 |

|

1.77 |

|

|

⅜ x 2¾ |

2.6 |

|

||||

80 |

88.9 |

|

34.5 |

150 |

|

21.40 |

0~1.6 |

|

114 |

151 |

|

45 |

|

|

M10 x 70 |

1.2 |

|

||||

|

108.0 mm |

4.250 |

|

500 |

300 |

|

7080 |

0~0.13 |

|

5.38 |

7.00 |

|

2.00 |

|

|

⅜ x 2¾ |

3.6 |

|

|||

|

108.0 |

|

34.5 |

150 |

|

31.59 |

0~3.2 |

|

137 |

219 |

|

51 |

|

|

M10 x 70 |

1.7 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

4 |

4.500 |

|

350 |

300 |

|

5560 |

0~0.13 |

|

5.63 |

7.48 |

|

2.00 |

|

|

⅜ x 2¾ |

3.6 |

|

||||

100 |

114.3 |

|

24.1 |

150 |

|

24.72 |

0~3.2 |

|

143 |

190 |

|

51 |

|

|

M10 x 70 |

1.7 |

|

||||

|

133.0 mm |

5.250 |

|

350 |

300 |

|

7570 |

0~0.13 |

|

6.52 |

8.61 |

|

2.00 |

|

|

½ x 3 |

4.6 |

|

|||

|

133.0 |

|

24.1 |

150 |

|

33.46 |

0~3.2 |

|

166 |

219 |

|

51 |

|

|

M12 x 75 |

2.1 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

139.7 mm |

5.500 |

|

350 |

300 |

|

8310 |

0~0.13 |

|

6.77 |

9.21 |

|

2.00 |

|

|

½ x 3 |

4.6 |

|

|||

|

139.7 |

|

24.1 |

150 |

|

36.92 |

0~3.2 |

|

172 |

234 |

|

51 |

|

|

M12 x 75 |

2.1 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

5 |

5.563 |

|

350 |

300 |

|

8500 |

0~0.13 |

|

6.89 |

8.98 |

|

2.00 |

|

|

½ x 3 |

4.6 |

|

||||

125 |

141.3 |

|

24.1 |

150 |

|

37.77 |

0~3.2 |

|

175 |

228 |

|

51 |

|

|

M12 x 75 |

2.1 |

|

||||

|

159.0 mm |

6.250 |

|

350 |

300 |

|

10730 |

0~0.13 |

|

7.50 |

9.67 |

|

2.00 |

|

|

½ x 3 |

4.4 |

|

|||

|

159.0 |

|

24.1 |

150 |

|

47.83 |

0~3.2 |

|

191 |

246 |

|

51 |

|

|

M12 x 75 |

2.0 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

165.1 mm |

6.500 |

|

350 |

300 |

|

11600 |

0~0.13 |

|

7.75 |

9.92 |

|

2.00 |

|

|

½ x 3 |

5.3 |

|

|||

|

165.1 |

|

24.1 |

150 |

|

51.57 |

0~3.2 |

|

197 |

252 |

|

51 |

|

|

M12 x 75 |

2.4 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

20130301 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||