Grooved-End Fittings |

G-07 |

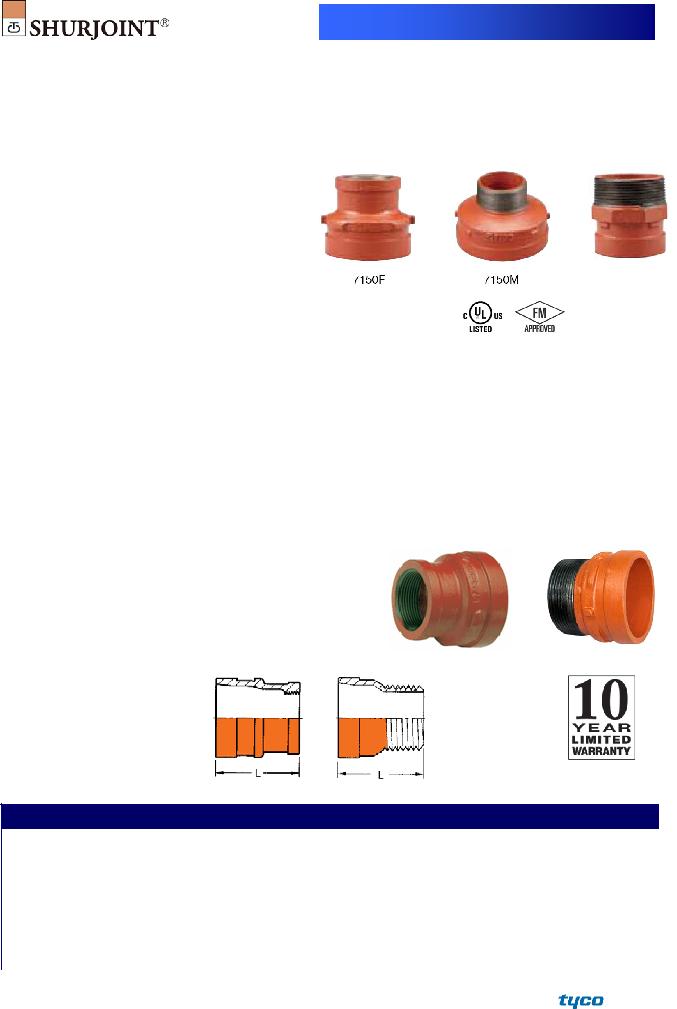

MODEL 7150F REDUCING SOCKET ADAPTOR (Gr x Ft) 7150M REDUCING NIPPLE (Gr x Mt)

55 NIPPLE ADAPTOR (Gr x Mt)

Shurjoint ductile iron grooved-end fittings are made of ductile iron per ASTM A536 Gr. 65-45-12 and or ASTM A395 Gr. 65-45- 15. C-E dimensions are manufacturer’s standard.

Shurjoint standard fitting pressure ratings conform to the ratings of Model 7707 couplings.

55

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet B-42 or visit SHURJOINT website, www.shurjoint.com for details or contact your SHURJOINT Representative.

MODEL 7150F REDUCING SOCKET ADAPTOR (Gr x Ft) 7150M REDUCING NIPPLE (Gr x Mt)

The Shurjoint Models 7150F & 7150M are designed for making direct reduction from a grooved system to female or male threaded system without the need for expensive swaged nipples.

Full warranty terms can be found on www.shurjoint.com

Model 7150F Reducing Socket Adapter, Model 7150M Reducing Nipple

|

Nom. Size |

Pipe |

|

7150F |

|

7150M |

Nom. Size |

Pipe |

|

7150F |

7150M |

|

Gr. X Th. |

OD |

L |

Weight |

L |

|

Weight |

Gr. X Th. |

OD |

L |

|

Weight |

L |

Weight |

|

in |

in |

in |

Lbs |

in |

|

Lbs |

in |

in |

in |

|

Lbs |

in |

Lbs |

|

mm |

mm |

mm |

Kgs |

mm |

|

Kgs |

mm |

mm |

mm |

|

Kgs |

mm |

Kgs |

|

1½ x 1 |

1.900 x 1.315 |

2.5 |

0.60 |

2.5 |

0.53 |

80 x |

3.500 x 3.000 |

2.5 |

2.20 |

2.5 |

2.20 |

|

40 x 25 |

48.3 x 33.4 |

63.5 |

0.27 |

63.5 |

0.24 |

76.1mm |

88.9 x 76.1 |

63.5 |

1.00 |

63.5 |

1.00 |

|

2 x 1 |

2.375 x 1.315 |

2.5 |

0.92 |

2.5 |

0.88 |

4 x 1¼ |

4.500 x 1.660 |

3 |

2.33 |

3 |

2.19 |

|

50 x 25 |

60.3 x 33.4 |

63.5 |

0.42 |

63.5 |

0.40 |

100 x 32 |

114.3 x 42.2 |

76.1 |

1.06 |

76.1 |

0.99 |

|

2 x 1¼ |

2.375 x 1.660 |

2.5 |

1.01 |

2.5 |

0.70 |

4 x 1½ |

4.500 x 1.900 |

3 |

2.05 |

3 |

2.05 |

|

50 x 32 |

60.3 x 42.2 |

63.5 |

0.46 |

63.5 |

0.32 |

100 x 40 |

114.3 x 48.3 |

76.1 |

0.93 |

76.1 |

0.93 |

G-07-1/3 Rev.H 20130301

|

|

|

|

|

|

|

Grooved-End Fittings |

|

G-07 |

|

|

|

|

|

|

|

|

Model 7150F Reducing Socket Adapter, Model 7150M Reducing Nipple |

|

Nom. Size |

Pipe |

|

7150F |

|

7150M |

|

Nom. Size |

Pipe |

7150F |

7150M |

Gr. X Th. |

OD |

L |

Weight |

L |

|

Weight |

|

Gr. X Th. |

OD |

L |

Weight |

L |

Weight |

in |

in |

in |

Lbs |

in |

|

Lbs |

|

in |

in |

in |

Lbs |

in |

Lbs |

mm |

mm |

mm |

Kgs |

mm |

|

Kgs |

|

mm |

mm |

mm |

Kgs |

mm |

Kgs |

2 x 1½ |

2.375 x 1.900 |

2.5 |

0.95 |

2.5 |

1.04 |

|

4 x 2 |

4.500 x 2.375 |

3 |

2.29 |

3 |

2.31 |

50 x 40 |

60.3 x 48.3 |

63.5 |

0.43 |

63.5 |

0.47 |

|

100 x 50 |

114.3 x 60.3 |

76.1 |

1.03 |

76.1 |

1.05 |

2½ x 1 |

2.875 x 1.315 |

2.5 |

1.21 |

2.5 |

0.88 |

|

4 x 2½ |

4.500 x 2.875 |

3 |

2.25 |

3 |

2.05 |

65 x 25 |

73.0 x 33.4 |

63.5 |

0.55 |

63.5 |

0.40 |

|

100 x 65 |

114.3 x 73.0 |

76.1 |

1.02 |

76.1 |

0.93 |

25 x |

3.000 x 1.315 |

2.5 |

1.21 |

2.5 |

1.64 |

|

4 x 2½ |

4.500 x 3.000 |

3 |

2.25 |

3 |

2.05 |

76.1mm |

76.1 x 33.4 |

63.5 |

0.55 |

63.5 |

0.75 |

|

100 x 65 |

114.3 x 76.1 |

76.1 |

1.02 |

76.1 |

0.93 |

2½ x 1¼ |

2.875 x 1.660 |

2.5 |

1.17 |

2.5 |

1.59 |

|

5 x 1½ |

5.563 x 1.900 |

3.5 |

3.94 |

3.5 |

2.05 |

65 x 32 |

73.0 x 42.2 |

63.5 |

0.53 |

63.5 |

0.72 |

|

125 x 40 |

141.3 x 48.3 |

88.9 |

1.79 |

88.9 |

0.93 |

32 x |

3.000 x 1.660 |

2.5 |

1.17 |

2.5 |

1.59 |

|

40 x |

5.500 x 1.900 |

3.5 |

3.94 |

3.5 |

2.05 |

76.1mm |

76.1 x 42.2 |

63.5 |

0.53 |

63.5 |

0.72 |

|

139.7mm |

139.7 x 48.3 |

88.9 |

1.79 |

88.9 |

0.93 |

2½ x 1½ |

2.875 x 1.900 |

2.5 |

1.08 |

2.5 |

1.72 |

|

6 x 1½ |

6.625 x 1.900 |

4 |

6.47 |

4 |

4.84 |

65 x 40 |

73.0 x 48.3 |

63.5 |

0.49 |

63.5 |

0.78 |

|

150 x 40 |

168.3 x 48.3 |

101.6 |

2.94 |

101.6 |

2.20 |

40 x |

3.000 x 1.900 |

2.5 |

1.08 |

2.5 |

1.72 |

|

40 x |

6.500 x 1.900 |

4 |

5.56 |

4 |

4.75 |

76.1mm |

76.1 x 48.3 |

63.5 |

0.49 |

63.5 |

0.78 |

|

165.1mm |

165.1 x 48.3 |

101.6 |

2.52 |

101.6 |

2.15 |

2½ x 2 |

2.875x 2.375 |

2.5 |

1.52 |

2.5 |

0.92 |

|

6 x 2 |

6.625 x 2.375 |

4 |

5.28 |

4 |

4.91 |

65 x 50 |

73.0 x 60.3 |

63.5 |

0.69 |

63.5 |

0.42 |

|

150 x 50 |

168.3 x 60.3 |

101.6 |

2.40 |

101.6 |

2.23 |

50 x |

3.000 x 2.375 |

2.5 |

1.52 |

2.5 |

1.09 |

|

50 x |

6.500 x 2.375 |

4 |

5.28 |

4 |

4.91 |

76.1mm |

76.1 x 60.3 |

63.5 |

0.69 |

63.5 |

0.49 |

|

165.1mm |

165.1 x 60.3 |

101.6 |

2.40 |

101.6 |

2.23 |

3 x 1 |

3.500 x 1.315 |

2.5 |

1.91 |

2.5 |

1.25 |

|

6 x 2½ |

6.625x 2.875 |

4 |

5.46 |

4 |

4.91 |

80 x 25 |

88.9 x 33.4 |

63.5 |

0.87 |

63.5 |

0.57 |

|

150 x 65 |

168.3 x 73.0 |

101.6 |

2.48 |

101.6 |

2.23 |

3 x 1¼ |

3.500 x 1.660 |

2.5 |

1.50 |

2.5 |

1.67 |

|

65 x |

6.500 x 3.000 |

4 |

4.40 |

4 |

4.97 |

80 x 32 |

88.9 x 42.2 |

63.5 |

0.68 |

63.5 |

0.76 |

|

165.1mm |

165.1 x 76.1 |

101.6 |

2.00 |

101.6 |

2.26 |

3 x 1½ |

3.500 x 1.900 |

2.5 |

1.63 |

2.5 |

1.53 |

|

6 x 4 |

6.625 x 4.500 |

4 |

6.37 |

4 |

4.52 |

80 x 40 |

88.9 x 48.3 |

63.5 |

0.74 |

63.5 |

0.74 |

|

150 x 100 |

168.3 x 114.3 |

101.6 |

2.89 |

101.6 |

2.10 |

3 x 2 |

3.500 x 2.375 |

2.5 |

1.56 |

2.5 |

1.32 |

|

100 x |

6.500 x 4.500 |

4 |

4.52 |

4 |

4.52 |

80 x 50 |

88.9 x 60.3 |

63.5 |

0.71 |

63.5 |

0.60 |

|

165.1mm |

165.1 x 114.3 |

101.6 |

2.10 |

101.6 |

2.10 |

3 x 2½ |

3.500 x 2.875 |

2.5 |

2.20 |

2.5 |

2.20 |

|

|

|

|

|

|

|

80 x 65 |

88.9 x 73.0 |

63.5 |

1.00 |

63.5 |

1.00 |

|

|

|

|

|

|

|

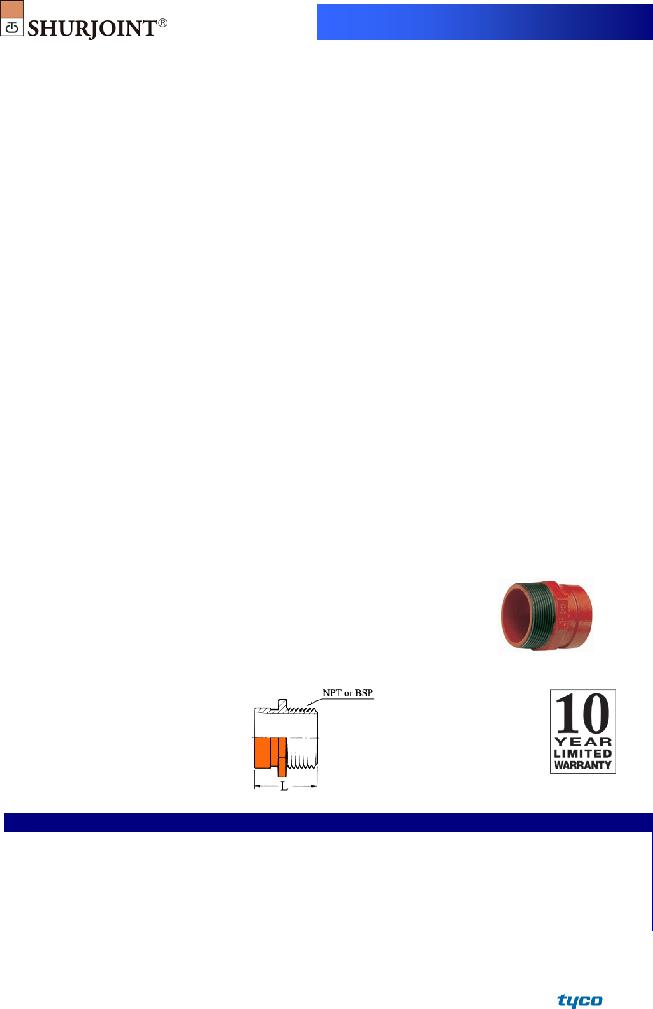

MODEL 55 NIPPLE ADAPTER (Gr x Mt)

The Shurjoint Model 55 is a cast adapter that allows for a direct transition from grooved system to a male threaded system. For other sizes, see our Model #59 pipe nipples.

Full warranty terms can be found on www.shurjoint.com

Model 55 Nipple Adapter

Nominal Size |

Pipe |

|

|

Grooves x Threaded |

OD |

L |

Weight |

|

|

|

|

in |

in |

in |

Lbs |

mm |

mm |

mm |

Kgs |

1½ x 1½M |

1.900 |

2.50 |

0.77 |

40 x 40M |

48.3 |

63.5 |

0.35 |

2 x 2M |

2.375 |

2.50 |

0.90 |

50 x 50M |

60.3 |

63.5 |

0.40 |

G-07-2/3 Rev.H 20130301

Grooved-End Fittings |

G-07 |

MATERIAL SPECIFICATIONS

• Fitting body:

Ductile Iron to ASTM A536, Gr. 65-45-12 and or ASTM A395, Gr. 65-45-15, min. tensile strength 65,000 psi (448MPa).

General Notes:

• Surface Finish:

Orange color painted or red RAL3000 color painted.

Hot dip galvanized. (Option)

Epoxy coated in red RAL3000 or other colors. (Option)

Pressure Ratings for fittings conform to the working pressure of the coupling used to join the system.

Listed and or Approved Pressures are pressure ratings for fire protection systems, tested and approved by various approval bodies. Please always refer to the latest approval data posted on the Shurjoint website.

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Job Name: |

System No. |

|

Location: |

Contractor: |

|

Approved: |

Date: |

Engineer: |

|

Approved: |

Date: |

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint products previously subsequently sold.

G-07-3/3 Rev.H 20130301

Trade Index Links