Grooved Fitting |

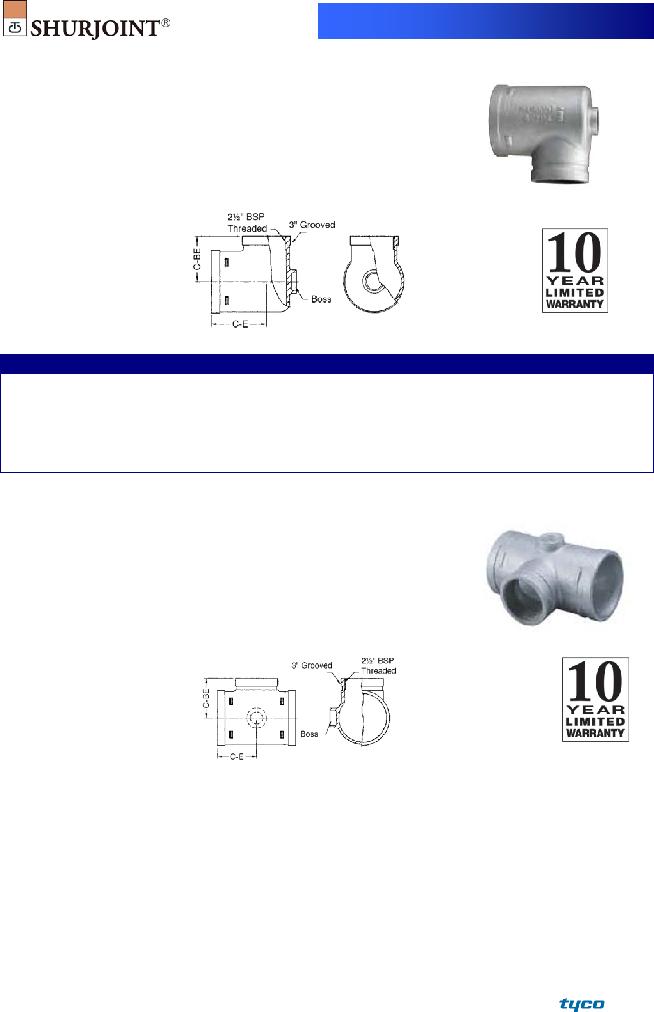

MODEL 7114 HYDRANT ELBOW

The Model 7114 Hydrant Elbow is designed for use on fire protection systems. The small end of the elbow is 2½" BSP threaded and also grooved to 3" pipe size. The boss can be factory tapped to 1" BSP on request.

Full warranty terms can be found on www.shurjoint.com

Model 7114 Hydrant Elbow

|

Nominal Pipe |

|

Pipe |

|

C - E |

|

C - BE |

|

Weight |

|

|

Size |

|

OD |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

in |

|

in |

|

in |

|

in |

|

Lbs |

|

|

mm |

|

mm |

|

mm |

|

mm |

|

Kgs |

|

|

4 x 3 x 1 |

|

4.500 x 3.500 x 1.315 |

|

4.00 |

|

3.75 |

|

5.95 |

|

|

100 x 80 x 25 |

|

114.3 x 88.9 x 33.4 |

102 |

95 |

2.70 |

|

|||

|

6 x 3 x 1 |

|

6.500 x 3.500 x 1.315 |

5.13 |

5.13 |

8.8 |

|

|||

|

150 x 80 x 25 |

|

165.1 x 88.9 x 33.4 |

130 |

130 |

4.0 |

|

|||

MODEL 7122 HYDRANT TEE

The Model 7122 Hydrant Tee is designed for use on fire protection systems. The 7122 is supplied with a 2½" BSP threaded and 3” grooved outlet. The boss can be factory tapped to 1” BSP on request.

|

|

|

|

|

|

|

|

Full warranty terms |

|

|

|

|

|

|

|

|

can be found on |

|

|

|

|

|

|

|

|

www.shurjoint.com |

|

|

|

|

|

|

|

|

|

|

|

|

Model 7122 Hydrant Tee |

|

|

|

||

|

Nominal Pipe |

|

Pipe |

|

C - E |

C - BE |

|

Weight |

|

Size |

|

OD |

|

|

|||

|

|

|

|

|

|

|

||

|

in |

|

in |

|

in |

in |

|

Lbs |

|

mm |

|

mm |

|

mm |

mm |

|

Kgs |

|

4 x 4 x 3 |

|

4.500 x 4.500 x 3.500 |

|

4.00 |

4.00 |

|

7.72 |

|

100 x 100 x 80 |

|

114.3 x 114.3 x 88.9 |

102 |

102 |

3.50 |

||

|

6 x 6 x 3 |

|

6.500 x 6.500 x 3.500 |

5.13 |

5.13 |

12.21 |

||

|

150 x 150 x 80 |

|

165.1 x 165.1 x 88.9 |

130 |

130 |

5.54 |

||