Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and/or inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal

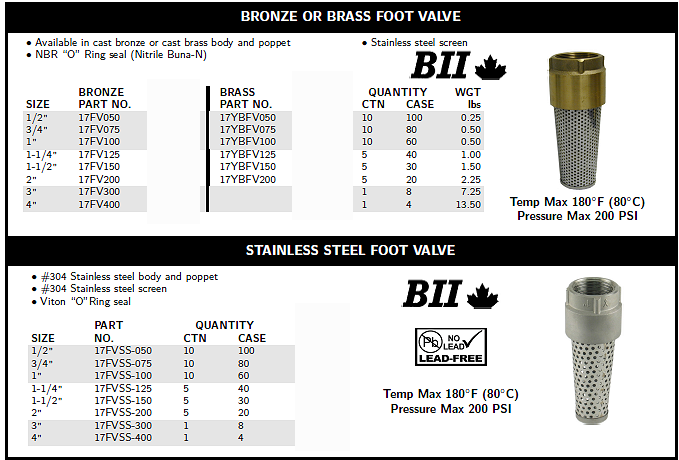

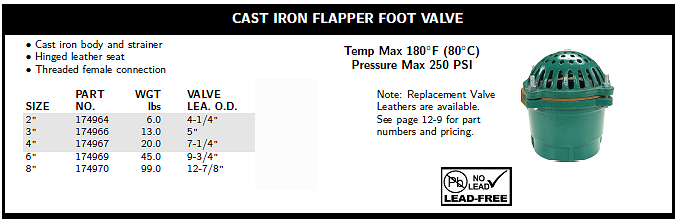

Foot valves are a form of check valve, installed at the bottom of Pump suction line, inside the wet well. Foot valves are an inexpensive way to prime a single centrifugal pump. The Foot Valve is designed with a 10% larger flow area (including heavy stainless steel strainer) than the pipe size to insure minimal head loss. Since Foot Valves are continually submerged in the wet well and not readily accessible for inspection or repair, it is important to select a Foot Valve of high quality long wearing construction. APCO Foot Valves are such valves and have heavy cast iron bodies, rugged bronze internals and most importantly they have drop tight resilient seating to guarantee no loss of suction.

Trade Index Links

Trade Index Links

FRASERS Industrial Supply Companies

www.canadianbusinessdirectory.ca